Voxelab Aquila - clone of the popular Ender 3 V2

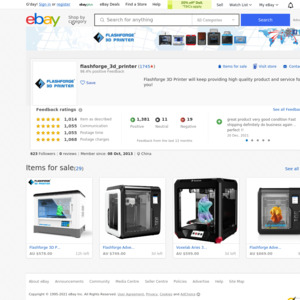

Voxelab Aquila 3D Printer $207.46 ($202.85 eBay Plus) & Free Shipping @ flashforge_3d_printer eBay

Last edited 20/07/2021 - 14:04 by 2 other users

Related Stores

closed Comments

- 1

- 2

No idea, just ordered tonight. Reviews seem fairly good, so I took the plunge for my first 3D printer.

Great printer, I got mine about a month or so ago. It works perfect out of the box (assuming you don't have any out of box issues) and have been tinkering with it since. There's a subreddit and multiple facebook groups for it as well with an activity community. Generally considered to be as good as the Ender 3 V2 but much cheaper. The company is the same as Flashforge which make high end printers, they made this brand to sell lower end value printers. I got mine a bit cheaper than this with a higher ebay discount and best offer from the same seller, but this isn't far off and it's a LOT of printer for the price.

Lots of youtube information available for this as well. If you're looking at getting into 3D printing this is a great start.

Are there any desirable upgrades you'd go for straight off the bat to improve the printer and overall experience?

No upgrades required, as it's a clone of the Ender 3 V2.

The iterations of the Ender printers are Ender 3, Ender 3 Pro, and then Ender 3 V2.

Only "upgrade" is replacing the PTFE tubing to Capricorn, just youtube "PTFE Capricorn tube Ender 3 replacement).

There's something called a "BL Touch", which helps auto-level your first layer to adhere to the print bed. This will ensure the print doesn't potentially warp or come off the bed mid print. I wouldn't invest in it until you familiarise yourself first.

I've been 3D printing 2 years straight, and the printer in this post is a definite 100% buy if you're intending to 3D print.

There's definitely money to be made, but you got to find a niche market that isn't saturated.

I make $70k+ per year from this side hobby (unfortunately I can't share what I do).

That's gangsta - gotta get into this hobby man..

@dandoon: All I can say is the internet is an unlimited source of information.

The learning curve is 3D designing and marketing/business.

I do believe everyone is capable of doing anything, just takes a lot of time and discipline.

@Ausdave: I appreciate it - I've shortlisted a 3d printer as my bday present for this year, so yeah you're absolutely right. With the internet I could really sink my teeth into a fun little side project, never know where it'll lead me. Thanks Ausdave!

@dandoon: This is what I've already earned this year:

https://imgur.com/a/oaqaznSHopefully give you motivation.

Once you build a portfolio and customer base it snowballs from there.

I have one question: With a store like Shopify, how do you actually get customers? With SEO there seems to be an overwhelming amount of information and nothing seems to work, google ads, facebook/instagram ads seem to be very expensive…

@wizko: Start off with instagram and/or facebook page without ads, and slowly build posts of your products there.

Add your website link to the IG/Fb page so customers can navigate to your website.

I suggest learning how to take good pictures of your product/s. I use a proper mirrorless camera (Sony A7iii), Godox sl-60w light with a softbox for taking pictures.

I then use Lightroom to edit Raw images, and then photoshop to crop/post process.

Not saying you should buy a good camera kit, I'm only pointing out if your images look sexy it will create a professional/legit impression on your business.

To be honest I only started paying for IG ads last week, only $2 a day. The rest was just organic follower progression.

Create an ABN for yourself as a sole trader, make revenue and put everything on tax (eg. printers, camera, raw materials, delivery costs etc.)

On another note: successful businesses in general (not talking about purely 3D printing) have a "point of difference", which separates them from their competition.

Establish your target market/demographic, and decide if you want to be a high end business or an affordable business.

My business is high profit margin and low volume, versus low profit high volume.

@Ausdave: Yep I see! I'm actually an eBay reseller and I've grown that business quite a lot over the last year (100K+ turnover) but I honestly feel suffocated by eBay and their daylight robbery selling fees.

I will take your advice and start an FB and IG page and hopefully I can start a shopify store from there on :)

Thanks!

@wizko: Awesome mate!

Annual cost:

Shopify: ~$800

Godaddy website address registration: ~$30

Microsoft 365 Email Essentials From GoDaddy (for Outlook email address and access): $120For IG/Fb, make weekly posts, interact with follower comments frequently, go to competing businesses and look up their followers and then request a follow. I'm sure you know all this already though :)

@Ausdave: Hi Ausdave,

You business sounds interesting, had no idea there was money to be made here.

Can I ask how many printers do you print with at the same time?

Thanks

@fredk1000: Four printers.

They don't take much power, it's about ~5-8 cents of electricity per hour each.

PLA filament is cheap also, $20-25 per kilo.

You can make a kilo worth of products for $25, plus overheads of course.I'm a structural engineer with a mechanical engineering background, so I have a bit of a head start on many people.

The skill set of 3D designing is very valuable. You can essentially look at a product or picture and replicate it.

Most products in the world is to facilitate convenience, and 3D printing is a tool to make that happen.

@Ausdave: Thanks for the reply.

What brand of filament do you use?

I only like using PLA on my printer, my printer bed is still scarred from using ABS once.I generally model and print repair parts for around the house, random cases for electronic projects and print small characters for the kids now and then.

Not much else.

My business is high profit margin and low volume, versus low profit high volume.

Dave, I can understand you not wanting to give too much away so feel free to tell me to get knicked but the above but this seems like quite a hard thing to pull off with 3D printing? Especially reading that you're dealing with PLA so I feel like you must be dealing with cosmetic rather than functional (heat/UV etc) parts?

Can I poke any more about how you managed to make high end PLA parts? What's your average order worth?

I've just started learning my own modelling and printing with an eventual thought of monetising (for beer money initially) but in the niche I'm looking at (car interior modifications) it seems like a wide range of crap but functional products exist and then the better designs still aren't priced very high.

Cheers

@tellhimhesdreaming: Just an FYI, I don't just own 3D printers, I also own laser cutters, CNCs, and resin printers.

Wasn't my intention to buy all those, but my side hobby eventually expanded which required me to invest further.

There's definitely businesses/hobbyists that make money purely on just 3D printers, mine's not one of them. An example is making face shields, hair bands, hand hooks for opening doors/pressing buttons during the pandemic. That's now a saturated market and not worth your time.

For the the 3D printer side, I make $800 from 1kg of filament ($25).

Average order profit margin varies depends on the job, from $50 to $500, turn over per month is $8-13k gross profit (net you can halve that amount due to tax, raw materials, postage).

If I do engineering design work it's in the thousands, but that's my main career stuff and not hobby stuff.

Majority of my projects are non-structural, they are mostly cosmetic and functional items.

If you're looking at car interiors I recommend ABS, which the printer in this post doesn't accommodate with the stock components. You can upgrade a few things to make that happen, Youtube "Direct drive vs bowden 3D printing".

PLA doesn't play well in temperatures/environments above 45-60 degrees, and starts to warp. ABS has a higher melting point, and is generally more structurally sound.

I need to clarify my previous statement 'high profit margin and low volume, versus low profit high volume':

Are you going to market your product as a premium product, or a cheap product. My competitors essentially make similar products and sell for way less, but I've marketed my business as high end/quality through my sexy product images and website. People tend pay more for a branded product versus generic (my experience anyway).Below are some successful businesses that use 3D printers for automotive related prototyping and also end products:

https://www.youtube.com/watch?v=eh9jb5W5rhw

https://www.youtube.com/watch?v=r6f7bc_J_hsYou're most likely going to start out making a lot of custom parts for clients, and eventually have a portfolio/template of designs you can mass produce and resell.

I'm at the point where I don't do anymore custom work, as the time spend going back and forth with customers, versus me just making my own designs and mass producing is more profitable (total time spend vs. cost turnover).

Edit: Not sure of your background, but social media, photography, marketing played a big role in my so called success.

@Ausdave: Really appreciate the info, it's nice to see someone making their own path with all the tools I wish I had in my non-existent workshop! Wish you all the best

@ausdave Just wondering if you know if this model can use any 1.75mm PLA (beginner here, not sure if brand/diameter matters). The seller of this model has several PLA types in their shop but none specifically say they work for this model.

@GirlFriday: 1.75mm:

https://www.voxelab3dp.com/comparison-between-aquila-3d-prin…1.75mm is the standard for majority of all 3D printers in the world.

Brand does matter in a sense of quality print outputs. I've mentioned two places I purchase from in previous comment.

Besides the mechanical side of things (physical printer), there are 2 other aspects I suggest researching:

1. 3D CAD software: Most use Autodesk Fusion 360 to 3D design, or you can get predesigned CAD models on the internet such as https://www.thingiverse.com/

2. Printing command software: Youtube "Cura 3D printing tutorial" etc., this program is free and manages all your 3D printing parameters such as temperature, layer heights, speed etc.For PLA 1.75mm filament, a good starting point is 195-205 degrees, 55-60 degrees bed temp, with a retraction of 5.5-6.5mm for bowden type printers like this (when you Youtube Cura settings you'll know what I'm talking about).

When you get a bit more advanced, Youtube "3D printing maintenance" and "optimising/installing Marlin custom firmware".

Thanks for the info.

One question.. do you provide warranty on your products? How does that work?

@superm86: Totally depends what industry you're making it for.

There is warranty and insurance.

For warranty, very simple, look at your competitor's website and check what they do for warranty.

For insurance, there is business, home, and product insurance (I'm generalising here):

Business insurance: google it and call companies up.

Home (maybe also contents) insurance: if your machines catch on fire and burn your home/garage down, see if they cover it.

Product insurance: again, totally depends on your product category. Look up product liability insurance.

I make $70k+ per year from this side hobby (unfortunately I can't share what I do).

mulletmods ??

@Bowchkawowow: I don't have this printer, I have the Ender 3 Pro and Ender 3 V2.

In saying that though, Voxelab Aquila 3D is almost an exact replica of those Ender machines.

Most components that are on the Ender 3 printers are replacable on the Voxelab.

What you're after is a "4010" fan (40x10mm) for the front fan on the extruder. Take the front fan case mount out and check the stock fan to see if it's 12 or 24V, then buy accordingly.

Keep in mind you need to buy a fan that has a long cable, cause it loops along the bowden tube (tube that has the filament), and then runs down into the mainboard.

If you're after silent fans, you can look into "Notua fan replacement Ender 3" on youtube, but requires buying a voltage regulator (buck converter) to match either 12/24V.

I do see a few vids on youtube for fan replacements for Voxelab also.

If you're after more efficient cooling fans, there are 4020 (40x20mm) fans available on Amazon, Aliexpress etc. This will require you to 3D print a custom fan housing.

I assume there is also a fan on the right hand side of the extruder (known as a fan blower), same fundamentals I've suggested above apply.

There's also a PSU fan, people replace that with a 80mm notua fan for quieter operation, it doesn't have any other benefit though. Yes it blows more CFM, but the stock fan I'm sure works fine.

I've personally haven't done anything I said above at all (even though I've purchased all the components to do so), I've only replaced my printers with the official stock fans from Aliexpress because my prints come out fine.

Only reason I'd upgrade/replace is just for tinkering fun.

Probably the extruder, you can get a bmg clone from aliexpress or amazon, the stock one tends to break or the bowden tube slips out of it(from what I've seen from other aquila and ender 3v2). Mine works fine atm but I have one on hand just in case, you can also print one out as well.

PTFE bowden tube - capricorn is the brand that gets recommended

BL touch for a auto bed leveling sensor, a Raspberry pi 3 or 4 to work alongside the BLtouch, those orange springs or silicon spacers for the bed, binder clips to hold the glass since it only comes with two clips.Oh right you probably would want a flush side cutter(to cut filament) since for some reason it doesn't come with it but other printers brands do supply you one.

I might change to quieter fans in the future but the noise is somewhat bearable haha.

I've been using mine stock atm for two weeks now and it's been going great. One thing I need to learn is patience lol, a print can take up hours and lowkey might jump on this deal to get a second aquila.

I would caution everyone, don't upgrade anything until you require it. I read this advice from many sources before I got mine, and while my initial prints were perfect I decided that I could get better by upgrading. At the time I did know the potential benefits would be from the upgrade, but at the same time they were not required and were just fueled by my desire to tinker and believe that it would be "better" after. I went from a working printer to a printer having problems in many ways and only just managed to get everything back in order the other day and it still has a few smaller tweaks required.

The problem is 3D Printers are very sensitive and precise machines, every change you make will require reconfiguration that will require either knowledge, equations and measuring equipment like calipers. For example, I replaced my perfectly working stock extruder with a BMG clone and guessed the new esteps based on watching tutorials on calculating them and actually got them bang on. However recently the BMG clone extruder had started eating my filament and spooling it around inside, in my attempts to clear and fix this, the tubing going to the hot end was getting mangled so I've had to cut it down a couple of times and is now shorter. This means my esteps are no longer correct and would have to calibrate it again. While there can be more technical reasons to replace the extruder, the stock one works fine and is mainly replaced only once it breaks but it's probably worth having a replacement ready to swap over when/if that happens rather than going straight to it.

Many people are getting great results from the stock machine as long as you're sticking to PLA for now. Stay with that for now, learn the machine and 3D printing theory in general and the upgrades you need will become clear when they're required. The main upgrades I would recommend to start with is the stronger yellow springs for the bed as the stock springs adjust themselves just from looking at them.

Capricorn PTFE tubing is a requirement if you want to print above PLA, but it's very precise in measurement and is known to cause problems if your filament isn't very accurate in thickness. The stock one works fine with PLA.

Got one! I built my one Prusa I3 like 8 years ago and didn't move it with me to Australia…. The obsession starts again… Gona spend hours watching the hot end come and go… And try to make the curta once more (https://www.thingiverse.com/thing:1943171)

is this good for a starter newbie?

Ah well I bought one :) $202.85 is a great price.

It's perfect for a starter, watch a few unboxing/setup videos and you'll generally be ready to print. Join the facebook groups if you use facebook. Most guides/videos for the Creality Ender 3 V2 generally apply to this printer as well which opens up the resources too.

Oos :(

Damn, I missed out.

seems to be more added

Got one, cheers! Down to $201.24 with Suncorp Benefits 3% off eBay gift cards.

Hmm I think they removed the stock as ebay states I bought the second last one, I thought there was over the 10 in stock at the time….. but a lot was sold lol

It's back in stock. I think they just took it down because they were getting alot of submitted best offers.

Back in stock

Has anybody made a purchase but only received a PayPal invoice and it not showing up on the Purchase section? I used the plus12off code instead of posted one

I paid by PayPal, plus10off coupon, and just received email from eBay with tracking number.

What was the time delay between order and email from eBay and not just PayPal? Normally would get the ebay email a minute after the PayPal one. Also could you see the purchase on your account. Mine still isn't showing on my ebay account

Ordered last night. PayPal invoice arrived instantly. Order was also showing in eBay. Email with tracking number from eBay this arvo.

Yep it happened sometimes with me especially if my cart contained multiple items, took a bit of time for it to show up.

Anyone know if it comes with filament, or do i need to but that separately.

only small amount for testing is included I believe. Need to purchase separately.

Been looking to get into 3D printing for years, finally decided to buy one.

Now just gotta looking into some decent filament that won’t cost a fortune..

Ive had a quick look but its confusing lol

the seller of this machine sells the stuff too

and Ausdave put this link here cubictech.com.au but they seem sold out of most of the PLA colours

cubictech distributes eSun filament and resins and had a massive sale recently hence the reason for them being out of stock on most filamnets at the moment. I do recommend them when they get back in stock though.

If you haven’t seen already, cubictech have them all back in stock. Ordered 3x1kg eSun filaments yesterday afternoon. Thankfully the postage price stays the same even when ordering multiples!

Which PLA brand / store do you guys recommend?

esun pla+ from cubictech, but I bought two(purple and black) from LONENESSL on amazon for that one day shipping and it worked out fine as well

Thanks! Ended up getting eSun Pla+ from some ebay eller

Did I miss out on the codes? Looks like they don’t work for this printer now, price is at $230.51 - or I’m doing something stupid.

Looks like its still available. Make sure you add it to cart and then when you go to checkout use the code SAVER10OFF in the coupon bit (end of the page). Should come down to 207.46.

Yeah, tried that, I get ‘This code can’t be applied to your order’.

Tried a few different payment methods but no good.

Maybe I’ve been naughty? :(

i wonder if you have the right seller? it should be flashforge_3d_printer. Is there anything special with your account? (registered in another country?)

@GirlFriday: Aha. Yes, probably something with the account - it started it’s life in the UK many many moons ago. A bit like PayPal - for what they touted as the galaxy’s best payment system a while ago it too really struggled with the concept of international travel :)

@OnlineOffline: I have the same problem. eBay and PayPal started in AU, then I moved to the UK and tried to get it changed. Moved back tried to get it changed back. Hilarity did not ensue.

Try changing your various country/ies in your account to AU.

Heh. Looks like I now have a new eBay account in Aus and eBay gets another wasted account; but I save my 20 odd bucks :)

Same happened to me… same solution hahaha

Thanks OP! Been thinking for a long time to get a 3d printer but it seems too hard and time consuming but watching some youtube about this printer, I think I am game enough to try. Plus it does not cost an arm and a leg!

Like a few that have asked, what PLA/PLA+ brand to get that is value for $? Thanks

For people asking about filament, in addition to Ausdave's advice I found this video which went over everything a newbie should know, filament types start at 12:34.

Just chiming in to say I also grabbed this in a previous sale/deal ($229) as my first printer and has been great to use so far albeit still a bit fiddly learning about getting the perfect first layer etc. But very impressive final results, also is an incredibly accessible hobby with modelling software being free for hobby use etc.

Stupidly tempted to get another one and set one for PETG and one for PLA….

Why stop there. Set up another with TPU

Now we're talking!

ABS?

Hey just curious what do you 3D print most of the time?

Ive been watching 3DPrintSOS on youtube and its the best source of knowledge I've been able to find :)

Yep me too. Good videos on the Aquila.

Anyone received delivery… I have a bunch of packages all at the same depot that are getting delivery but the printer is just sitting there it seems 😅

Who did they send it with?

AusPost

mines been sent thru aramex and i ordered on wednesday morning and the tracking number is saying its expected to arrive to wollongong on tuesday

Ordered Wednesday. Delivered today.

Ordered monday, before the 100+ orders that followed. Has been idle since Tuesday.

It's on its way

Most recent updateItem processed at facility

DANDENONG SOUTH VIC

ordered Tuesday afternoon and received it today

Yep received

Ordered Monday night, got it on Sunday (didn’t know deliveries were done on Sunday’s)

Printed test files on sd card, amazing print quality for the price, but the test files have astonishing slow speeds….

Also, the testing filament is not enough for the tool box, don’t ask how I know…..

Dam I literally just started it with the test filament

And does are all the prints as slow as the test prints shipped with the printer

And does are all the prints as slow as the test prints shipped with the printer

What extruder are people planning to use? I read very bad things about the stock one.

I ordered this one:

https://www.aliexpress.com/item/Bowden-Clone-Dual-Drive-Gear…

I ordered it in right which I hope is correct!

Bought some replacement springs as well:

https://www.aliexpress.com/item/Heated-Bed-Springs-Die-Light…

I have a BLTouch on my Ender 3 but I think Ill try manually levelling this time.

DD really wasn't necessary unless all your printing is TPU or ABS, just adding more weight to the head.

I would of skipped the yellow springs for the silicone spacers. Even with a Bltouch you need to do a level check with the paper. Bltouch doesn't make it a autoleveling bed, just gives a slight x-axis adjustment to help

All the people in the subreddit recommend the DD. Which mods have you done?

Are you changing all this before you have used it stock?

No I'm going to run stock first.

Hey mates, do you think it's ok to pay with afterpay for this seller. I have seen few issues in the past month or should I go with Paypal? Thanks

Oh If it gets back in stock it could be bought for AU $191.32 with the coupon PSAVE17

I received mine and tried to make the toolbox, test filament ran out ffs :(

But it runs nice and was easy to set up :)

I just received my printer today and box was damaged- hopefully no issues with the printer.

Any tips for newbies to setup and use?! I know there’s heaps of stuff online and on YouTube, it’s abit overwhelming so keen to hear your experience since you just received it. Thanks :)

- 1

- 2

Any good?